Vortex Tubes

Using only filtered, factory compressed air as a power source, vortex tubes convert ordinary compressed air into two air streams -- one hot and one cold.

Features | Specifications

VORTEX TUBES

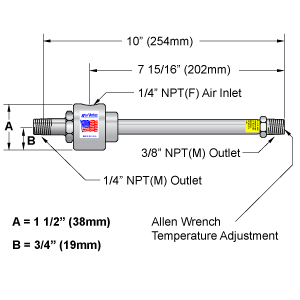

Vortex tubes produce up to 6000 BTU/hr (1757 watts) of refrigeration and temperatures as low as -40 deg to solve a variety of industrial spot cooling and process cooling needs. With no moving parts, a vortex tube is highly reliable and inexpensive; and requires no electrical connection at the cooling site. Vortex tubes cool instantly, relying on compressed air spinning in the tube to separate the air into cold and hot air streams.

Vortex tubes are a compact source of refrigeration and cooling, with models ranging from 6 – 13 inches (150 – 330 mm) long and cooling capacities ranging from 100 – 6000 BTU/hour (29 – 1757 watts). Vortex tube performance is easily adjustable by changing the inlet air pressure, ratio of cool air to exhaust or by changing the generator in the tube itself. And while normally used for cooling, vortex tubes can also be used for heating applications, merely by channeling the exhaust hot air to the application.

Vortex tube technology was invented by French physicist Georges Ranque in 1930, and first developed for industrial use by Vortec in the 1960s. Since then, vortex tubes have been applied for a wide range of cooling applications on machines, assembly lines, in processes and for testing and measurements.

BENEFITS

- Cools instantaneously

- Lowest cost per unit of refrigeration of any cooling technique

- Fully adjustable cooling, easily moved from site to site as needed

- Fits to provide cooling in the most confined areas

- Lowest maintenance requirements of any refrigeration technique

- Environmentally friendly, with no refrigerants or chemicals needed

- Easy to install, just connect compressed air and go

FEATURES

- Maintenance free, with no moving parts

- Cycle repeatability within +/- 1 deg

- Drops compressed air inlet temperature by up to 100 deg F (55 deg C)

- No electricity required at the cooling site

- Cools without refrigerants, as low as -40 deg

- Compact and lightweight, highly transportable

- Adjustable for varying cooling needs

- Available heating capacity using the same tube, up to 200 deg F (93 deg C)

- Available in both aluminum (208 and 308) and stainless steel (208SS) models

- Replacement generators available for modification of cooling or upon contamination

SPECIFICATIONS

| Model# | VOR.106-2-H | VOR.106-4-H | VOR.106-8-H | VOR.208-11-H |

| Material of Construction | Brass/Stainless Steel | Brass/Stainless Steel | Brass/Stainless Steel | Aluminum |

| Inlet, inch, NPT | 1/8 | 1/8 | 1/8 | 1/4 |

| Cooling Capacity (BTU/hr) | 100 | 200 | 400 | 640 |

| Air Consumption @ 100 psig (scfm) | 2 | 4 | 8 | 11 |

| Inlet, Female or Male | F | F | F | F |

| Model# | VOR.208-25-HSS | VOR.308-35-H | VOR.328-50-H | VOR.328-75-H | VOR.328-100-H |

| Material of Construction | Stainless Steel | Aluminum | Aluminum | Aluminum | Aluminum |

| Inlet, inch, NPT | 1/4 | 1/4 | 1/2 | 1/2 | 1/2 |

| Cooling Capacity (BTU/hr) | 1500 | 2650 | 3000 | 4500 | 6000 |

| Air Consumption @ 100 psig (scfm) | 25 | 35 | 50 | 75 | 100 |

| Inlet, Female or Male | M | F | M | M | M |

Technical stuff for information only

Due to the fact that we are continuously improving our products, the descriptions, illustrations, specifications,dimensions, and part numbers are subject to change without notice. Every effort has been made to have the information on this site error free, we can not be responsible for errors and or omissions.

ITW Vortec's vortex tube products have

been solving industrial cooling problems for years. Using only

filtered, factory compressed air as a power source, they convert

ordinary compressed air into two air streams -- one hot and one

cold. At 100 PSIG (6.9 Bar) and 70° F (21° C) inlet temperature,

a vortex tube can produce refrigeration up to 6000 BTUH (1512

kcal/H) or temperatures to -40° F (-40° C).

Choose one of our Cold Air Guns for quick, easy installation or the model from our complete vortex tube line that best fits the specific needs of your application.

| Vortex Tube Models and Performance Specifications: | ||||||||

| MODEL NO. | COMPRESSED AIR PRESSURE -- 100 PSIG | COMPRESSED AIR PRESSURE -- 6.9 BAR |

|

|||||

|

SCFM CONSUMPTION |

TEMP. DROP ° F* |

BTUH | SLPM |

TEMP. DROP ° C* |

||||

| CONSUMPTION | KCAL/H | |||||||

| VOR.106-2-H | 2 | 61 | 100 | 57 | 34 | 25 |

|

|

| VOR.106-4-H | 4 | 80 | 255 | 113 | 44 | 64 | ||

| VOR.106-8-H | 8 | 81 | 400 | 227 | 45 | 101 | ||

| VOR.208-11-H | 11 | 84 | 640 | 312 | 47 | 161 |

|

|

| VOR.208-15-H | 15 | 84 | 900 | 425 | 47 | 227 | ||

| VOR.208-25-H | 25 | 67 | 1500 | 708 | 37 | 378 | ||

| VOR.308-35-H | 35 | 76 | 2650 | 992 | 42 | 668 |

|

|

| VOR.328-50-H | 50 | 79 | 3000 | 1416 | 44 | 756 |

|

|

| VOR.328-75-H | 75 | 85 | 4500 | 2125 | 47 | 1134 | ||

| VOR.328-100-H | 100 | 78 | 6000 | 2833 | 43 | 1512 | ||

BTUH (kcal/H) capacity based upon 70° F (21° C) compressed air dried to a dewpoint of -40° F (-40° C).

* Airflow temperature can be dropped up to an additional 20° F (11° C). Colder airflow temperatures are produced by adjusting the needle valve to increase the hot airflow. The needle valve is located in the hot exhaust. Vortex Tubes produce less airflow at colder temperatures and have less BTUH (kcal/H) capacity.

Accessories:

| MODEL NO. | DESCRIPTION |

|---|---|

| VOR.106GEN | Individual Generator for VOR.106 Vortex Tube -- specify 2, 4 or 8 SCFM |

| VOR.106MC | Cold End Muffler for VOR.106 Vortex Tube |

| VOR.208GEN | Individual Generator for VOR.208 Vortex Tube -- specify 11, 15, 25 or 35 SCFM |

| VOR.208MC | Cold End Muffler for VOR.208 or VOR.308 Vortex Tubes |

| VOR.208MH | Hot End Muffler for VOR.106 or VOR.208 Vortex Tubes |

| VOR.308MH | Hot End Muffler for VOR.308 Vortex Tube |

| VOR.328M | Cold or Hot End Muffler for VOR.328 Vortex Tube |

| VOR.328XB | Individual Generator for VOR.328 Vortex Tube -- specify 50, 75 or 100 SCFM |

Operation

Any fluid that flows and rotates about an axis such as a tornado,

is called a vortex. A vortex tube creates a vortex and separates

it into two air streams-one hot and one cold. Figure 1 shows how

a vortex tube works. Compressed air enters a cylindrical generator

which is proportionately larger than the hot (long) tube. The

generator causes the air to spiral. The spiraling air is forced

down the inner walls of the hot tube at speeds reaching 1,000,000

rpm. At the end of the hot tube, a small portion of this air exits

through a needle valve as hot air. The remaining air is forced

back through the center of the incoming air stream but at a slower

speed. The heat in slower moving air is transferred to the faster

moving incoming air. This super-cooled air flows through the center

of the generator and exits through the cold air exhaust port.

Temperature Separation Effects

The Vortex Tube Creates two types of vortices: free and forced.

In a free vortex (like a whirlpool) the angular velocity of a

fluid particle increases as it moves toward the Center of the

vortex-that is, the closer a particle of fluid is to the center

of a vortex, the faster it rotates. In a forced vortex, the velocity

is directly, proportional to the radius of the vortex-the closer

the center, the slower the velocity.

In a vortex tube, the outer (hot) air stream is a free vortex.

The inner (cold) air stream is a forced vortex. The rotational

movement of the forced vortex is controlled by the free vortex

(hot air stream). The turbulence of both the hot and cold air

streams cause the layers to be locked together in a single, rotational

mass.

The inner air stream flows through the hollow core of the outer

air stream at a slower velocity than the outer air stream. Since

the energy is proportional to the square of the velocity, the

cold air stream loses its energy by heat transfer. This allows

energy to flow from the inner air stream to the outer air stream

as heat creating a cold inner air stream.

Cold Fraction

The percentage of total input air volume released through the

cold air exhaust of a Vortex Tube is called the Cold Fraction.

A valve located in the hot air exhaust of the Vortex Tube controls

the Cold Fraction. For example, if the total compressed air input

is 15 SCFM (424.5 SLPM) and the Cold Fraction is 70%, the amount

of air exiting the cold end wilt be 10.5 SCFM (297.2 SLPM); 4.5

SCFM (127.4 SLPM) exits the hot end.

Cold Fractions of 60-80% produce maximum efficiency-greatest power

(BTUH) output- and are ideal for cooling machining operations,

electrical controls and enclosures, liquid baths and workers.

Low Cold Fractions (less than 50%) have reduced airflows and produce

the lowest temperatures for cooling glass, laboratory experiments

and for testing electronic components.

|

Temperature ° F(° C) |

110(43) | 100(38) | 90(32) | 80(27) | 70(21) | 60(16) | 50(10) | |

|

Saturation, gr/lb(gr/kg) |

375(827) | 295(650) | 217(478) | 154(339) | 111(245) | 77(170) | 54(119) | |

|

Temperature ° F(° C) |

40(4) | 30(-1) | 20(-7) | 10(-12) | 0(-18) | -10(-23) | -20(-29) | -30(-34) |

|

Saturation, gr/lb(gr/kg) |

37(82) | 24(53) | 15(33) | 9(20) | 5.5(12) | 3.2(7) | 1.8(4) | 1.0(2) |

|

Temperature ° F(° C) |

110(43) | 100(38) | 90(32) | 80(27) | 70(21) | 60(16) | 50(10) | 40(4) | 30(-1) | 20(-7) |

|

Saturation, gr/lb(gr/kg) |

48(106) | 38(84) | 28(62) | 20(44) | 14(31) | 9.8(22) | 6.9(15) | 4.7(10) | 3.1(7) | 1.9(4) |

Humidity Effects

A Vortex Tube does not separate humidity between hot and cold air-it remains the same as the compressed air input. If the dew point of the air is higher than its temperature, the moisture will condense and/or freeze. The table above shows the amount of moisture in grains (1 grain = 0.000143 pound) that one pound of air can hold in the saturated vapor state as a function of air temperature at one atmosphere, 14.7 PSIG (1 D Bar). Table 1 shows when condensation will begin at various temperatures and moisture contents. For example, if the moisture content is 14 gr/lb (31 gr/kg), condensation will begin when the temperature of the cold air falls below 19 ° F(-7.2° C) At 5 gr/lb (11 gr/kg), condensation will begin at -1° F (-18° C).

If you compare Tables 1 and 2, you can predict the amount of moisture in the compressed air and the temperature at which the moisture will begin to precipitate or freeze in the cold air. For example, if the compressed air is after-cooled to 80° F (27° C) after compression and the precipitated water is drained off, Table 2 shows that the air will hold 20 grains of water vapor per pound of dry air. When this expands in the Vortex Tube, Table 1 shows that precipitation begins in the cold air when the temperature falls below 26° F (-3.3° C) when the pressure is 14.7 PSIG (1.0 Bar)

If the compressed air is cooled under pressure by a chiller to 40° F (4.4° C), it will then hold 4.7 gr/lb of water vapor (see Table 2). When expanded in the Vortex Tube, precipitation will occur at -3° F (-19° C) at 14.4 PSIG (1 .0 Bar).

If some moisture precipitates in the cold air, the temperature of the cold air will rise about 0.75° F (0.4° C) for each grain of moisture precipitated. This is because some of the sensible (apparent) refrigeration of the cold air is consumed in producing latent refrigeration of the moisture. This refrigeration is not lost, but reappears in the cold air as it warms after leaving the Vortex Tube when the precipitated moisture evaporates.

For example, if a VOR.208-15-H Vortex Tube is operating at 100 PSIG (6.9 Bar), it will achieve a cold end temperature of approximately -15° F (-26° C) at a dew point of -40° F (-40° C) and a cold end flow rate of 10.3 SCF (291.5 SLPM). But if the compressed air supply was not dried, and only after-cooled to 80° F (27° C), it would contain 20 gr/lb of moisture. But once the cold air reaches -15° F (-26° C), Table 1 shows that the air can only hold 2.5 grains of moisture and 17.5 grains (20 - 2.5) of moisture would precipitate out. This would cause a temperature rise of over 13° F (7.2° C) causing a loss of 144 BTUH (36 kcal/H).

Tables 1 and 2 show that condensation will not normally occur at moderately cold temperatures. When temperatures are below freezing, the condensation is in the form of snow. This snow has a sticky quality from oil vapor and will eventually collect and block air passages. For continuous operation at low temperatures, use an air dryer or inject an antifreeze mist into the input air. When selecting a dryer, do not use chemical desiccant dyers such as silica-gel or molecular sieve types. They tend to heat the compressed air and cause refrigeration losses.

link to Vortec Products index page

February 2022, updated January 2019 , February 2017, December 2009 CSS, August 2007, February 2007,September 1998

The descriptions, illustrations, specifications, dimensions, and part numbers are subject to change without notice.

servicing the Canadian provinces and territories of Newfoundland, NF, NL, Nova

Scotia, NS, New Brunswick, NB, Prince Edward Island, PEI, PE, Quebec, PQ, QC, Ontario, ON,

Manitoba, MB, Saskatchewan, SK, Alberta, AB, British Columbia, BC, Northwest Territories, NT, Nunavut, NU, Yukon, YT,

servicing Canadian cities,

Toronto, Mississauga, Scarborough, Laval , Montreal, Montréal, Vancouver, Ottawa, Gatineau, Calgary, Edmonton, Québec City, Winnipeg, Hamilton, Kitchener, Cambridge, Waterloo, London, St. Catharines , Niagara, Halifax, Oshawa, Victoria, Windsor, Saskatoon, Regina, Sherbrooke, St. John's,

Barrie, Kelowna, Abbotsford, Mission, Sudbury Kingston, Saguenay, Trois-Rivieres, Trois Rivieres, Trois-Rivières, Guelph, Moncton, Brantford, Saint John, Thunder Bay, Peterborough,

Ajax, Aurora, Brampton, Brock, Burlington, Caledon, Clarington, Durham Region, Oshawa, Pickering, Whitby, Halton Hills, Milton, Oakville, Mississauga, New market, Richmond Hill, Vaughn, Orangeville,

servicing US cities,

New York, Los Angeles, Chicago, Houston, Philadelphia, Phoenix, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, San Francisco, Indianapolis,

Columbus, Fort Worth, Charlotte, Seattle, Denver, El Paso, Detroit, Washington, Boston, Memphis, Nashville, Portland, Oklahoma City, Las Vegas,

Baltimore, Louisville, Milwaukee, Albuquerque, Tucson, Fresno, Sacramento, Kansas City, Long Beach, Mesa, Raleigh, Omaha, Miami, Oakland,

Minneapolis, Tulsa, Wichita, New Orleans, Arlington, Cleveland, Bakersfield, Tampa,

Aurora, Honolulu, Anaheim, Santa Ana, Corpus Christi, Riverside, St. Louis, Lexington, Stockton, Pittsburgh, Saint Paul, Anchorage, Cincinnati,

Henderson, Greensboro, Plano, Newark, Toledo, Lincoln, Orlando, Chula Vista, Jersey City, Chandler, Fort Wayne, Buffalo, Durham, St. Petersburg, Irvine,

Laredo, Lubbock, Madison, Gilbert, Norfolk, Reno, Winston Salem, Glendale, Hialeah, Garland, Scottsdale, Chesapeake, North Las Vegas, Fremont,

Baton Rouge, Richmond, Boise, San Bernardino, Spokane, Birmingham, Modesto, Des Moines, Rochester, Tacoma, Fontana, Oxnard, Moreno Valley, Fayetteville,

Huntington Beach, Yonkers, Glendale, Aurora, Montgomery, Columbus, Amarillo, Little Rock, Akron, Shreveport, Augusta, Grand Rapids,

Mobile, Salt Lake City, Huntsville, Tallahassee, Grand Prairie, Overland Park, Knoxville, Worcester, Brownsville, Newport News, Santa Clarita,

Port St. Lucie, Providence, Fort Lauderdale, Chattanooga, Tempe, Oceanside, Garden Grove, Rancho Cucamonga, Cape Coral, Santa Rosa, Vancouver,

Sioux Falls, Peoria, Ontario, Jackson, Elk Grove, Springfield, Pembroke Pines, Salem, Corona, Eugene, McKinney, Fort Collins, Lancaster,

Cary, Palmdale, Hayward, Salinas, Frisco, Springfield, Pasadena, Macon, Alexandria, Pomona, Lakewood, Sunnyvale, Escondido, Kansas City, Hollywood,

Clarksville, Torrance, Rockford, Joliet, Paterson, Bridgeport, Naperville, Savannah, Mesquite, Syracuse, Pasadena, Orange, Fullerton, Killeen,

Dayton, McAllen, Bellevue, Miramar, Hampton, West Valley City, Warren, Olathe, Columbia, Thornton, Carrollton, Midland, Charleston, Waco

and the states

of Alabama, AL, Alaska, AK, Arizona, AZ, Arkansas, AR, California, CA, Colorado, CO, Connecticut, CT,

Delaware, DE, District of Columbia, DC, Florida, FL, Georgia, GA, Hawaii, HI, Idaho, ID, Illinois, IL, Indiana, IN,

Iowa, IA, Kansas, KS, Kentucky, KY, Louisiana, LA, Maine, ME, Maryland, MD, Massachusetts, MA,

Michigan, MI, Minnesota, MN, Mississippi, MS, Missouri, MO, Montana, MT, Nebraska, NE,

Nevada, NV, New Hampshire, NH, New Jersey, NJ, New Mexico, NM, New York, NY, North

Carolina, NC, North Dakota, ND, Ohio, OH, Oklahoma, OK, Oregon, OR, Pennsylvania, PA,

Rhode Island, RI, South Carolina, SC, South Dakota, SD, Tennessee, TN, Texas, TX,

Utah, UT, Vermont, VT, Virginia, VA, Washington, WA, West Virginia, WV, Wisconsin, WI, Wyoming, WY

We can ship to Afghanistan , Aland Islands , Albania ,

Algeria , American Samoa , AS, Andorra , Angola , Anguilla , Antigua

and Barbuda , Argentina , Armenia , Aruba , Australia , Austria

, Azerbaijan , Azores , Bahamas , Bahrain , Bangladesh , Barbados

, Belarus , Belgium , Belize , Benin , Bermuda , Bhutan , Bolivia

, Bonaire , Bosnia , Botswana , Brazil , British Virgin Isles

, Brunei , Bulgaria , Burkina Faso , Burundi , Cambodia , Cameroon

, Canada , Canary Islands , Cape Verde , Cayman Islands , Central

African Republic , Chad , Chile , China , Colombia , Comoros ,

Congo , Cook Islands , Costa Rica , Croatia , Curacao , Cyprus

, Czech Republic , Democratic Republic of Congo , Denmark , Djibouti

, Dominica , Dominican Republic , Ecuador , Egypt , El Salvador

, England , Equatorial Guinea , Eritrea , Estonia , Ethiopia ,

Faeroe Islands , Fiji , Finland , France , French Guiana , French

Polynesia , Gabon , Gambia , Georgia , Germany , Ghana , Gibraltar

, Greece , Greenland , Grenada , Guadeloupe , Guam , GU, Guatemala

, Guernsey , Guinea , Guinea-Bissau , Guyana , Haiti , Holland

, Honduras , Hong Kong , Hungary , Iceland , India , Indonesia

, Iraq , Ireland , Israel , Italy , Ivory Coast , Jamaica , Japan

, Jersey , Jordan , Kazakhstan , Kenya , Kiribati , Kosrae , Kuwait

, Kyrgyzstan , Laos , Latvia , Lebanon , Lesotho , Liberia , Libya

, Liechtenstein , Lithuania , Luxembourg , Macau , Macedonia (Fyrom)

, Madagascar , Madeira , Malawi , Malaysia , Maldives , Mali ,

Malta , Marshall Islands , MH, Martinique , Mauritania , Mauritius

, Mayotte , Mexico , Micronesia , Moldova , Monaco , Mongolia

, Montenegro , Montserrat , Morocco , Mozambique , N. Mariana

Islands , Namibia , Nepal , Netherlands , Netherlands Antilles

, New Caledonia , New Zealand , Nicaragua , Niger , Nigeria ,

Norfolk Island , Northern Ireland , Norway , Oman , Pakistan ,

Palau , PW, Panama , Papua New Guinea , Paraguay , Peru , Philippines

, Poland , Ponape , Portugal , Puerto Rico , PR, Qatar , Reunion ,

Romania , Rota , Russia , Rwanda , Saba , Saipan , San Marino

, Saudi Arabia , Scotland , Senegal , Serbia , Seychelles , Sierra

Leone , Singapore , Slovakia , Slovenia , Solomon Islands , South

Africa , South Korea , Spain , Sri Lanka , St. Barthelemy , St.

Christopher , St. Croix , St. Eustatius , St. John , St. Kitts

and Nevis , St. Lucia , St. Maarten , St. Martin , St. Thomas

, St. Vincent/Grenadines , Suriname , Swaziland , Sweden , Switzerland

, Syria , Tahiti , Taiwan , Tajikistan , Tanzania , Thailand ,

Timor Leste , Tinian , Togo , Tonga , Tortola , Trinidad and

Tobago , Truk , Tunisia , Turkey , Turkmenistan , Turks and

Caicos Islands , Tuvalu , Uganda , Ukraine , Union Island , United

Arab Emirates , United Kingdom , United States , Uruguay, US Virgin

Islands , VI, Uzbekistan , Vanatu , Vatican City State , Venezuela

, Vietnam , Virgin Gorda , Wales , Wallia and Futuna Islands

, Western Samoa , Yap , Yemen , Zambia , Zimbabwe

we try to ship to the world largest cities

Tokyo,Japan, Seoul, South Korea, Mexico City, Mexico , New York City, USA , Mumbai, India , Jakarta, Indonesia , Sáo Paulo, Brazil, Delhi, India , Osaka/Kobe, Japan , Shanghai, China , Manila, Philippines ,Los Angeles, USA ,Calcutta, India , Moscow, Russian Fed., Cairo, Egypt, Lagos, Nigeria, Buenos Aires, Argentina , London, United Kingdom , Beijing, China , Karachi, Pakistan , Dhaka, Bangladesh , Rio de Janeiro, Brazil ,Tianjin, China , Paris, France , Istanbul, Turkey , Lima, Peru , Tehrãn, Iran, Bangkok, Thailand , Chicago, USA , Bogotá, Colombia , Hyderabad, India , Chennai, India , Essen, Germany , Ho Chi Minh City, Vietnam , Hangzhou, China , Hong Kong, China , Lahore, Pakistan , Shenyang, China , Changchun, China , Bangalore, India , Harbin, China , Chengdu, China , Santiago, Chile ,Guangzhou, China , St. Petersburg, Russian Fed , Kinshasa, DRC , Baghdãd, Iraq , Jinan, China , Houston, USA , Toronto, Canada, Yangon, Myanmar (Burma), Alger, Algeria Philadelphia, USA, Qingdao, China , Milano, Italy , Pusan, South Korea, Belo Horizonte, Brazil, Almadabad, India , Madrid, Spain , San Francisco, USA, Alexandria, Egypt , Washington DC, USA , Wuhan, China , Dallas, USA , Guadalajara, Mexico, Chongging, China , Medellin, Colombia, Detroit, USA , Handan, China , Frankfurt, Germany , Porto Alegre, Brazil , Hanoi, Vietnam , Sydney, Australia, Santo Domingo, Dom. Rep., Singapore, Singapore , Casablanca, Morocco , Katowice, Poland , Pune, India , Bangdung, Indonesia, Monterrey, Mexico ,Montréal, Canada , Nagoya, Japan , Nanjing, China , Abidjan, Côte d'Ivoire, Xi'an, China , Berlin, Germany , Riyadh, Saudi Arabia, Recife, Brazil , Dusseldorf, Germany, Ankara, Turkey , Melbourne, Australia, Salvador, Brazil , Dalian, China , Caracas, Venezuela, Adis Abeba, Ethiopia,

Athina, Greece, Cape Town, South Africa, Koln, Germany , Maputo, Mozambique, Napoli, Italy